Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

DC Line Fully – Automation Production Line

PRODUCT INTRODUCTION

Machine Details:

The equipment meets the requirements of automatic wire feeding, wire straightening, wire cutting, core wire cutting by knife, wire stripping and twisting, automatic core separation, automatic adhesive applying of flux, automatic tinning, welding, detection, injection molding, automatic wire winding and bundling and other processes.

Function Highlights:

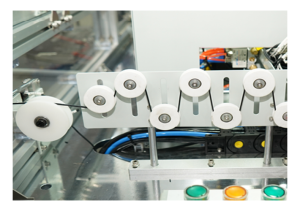

1. Automatic wire straightening

Precision motorized pay-off, straightening device efficiently eliminate the wires. Bending and twisting effectively ensure the accuracy of subsequent processing.

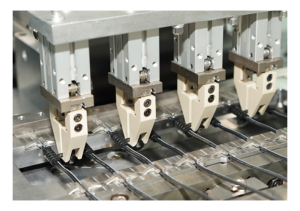

2. High-efficiency peeling and twisting :

The high-precision peeling tool precisely cuts the insulation layer of the core wire to ensure the accuracy of peeling. The twisting mechanism quickly and evenly twists the core wire and completes the peeling.

3. Waste treatment:

Manipulator automatic clip and waste out of injection nozzle, through the removal mechanism clears waste for efficient waste disposal.

4. Automatic wire winding and binding:

The DC wire is automatically wound, with a tight and neat winding. The high-efficiency wire binding device can complete the operation quickly, eliminating the need for manual intervention and effectively improving production efficiency.

Application field:

This equipment is mainly applied to the consumer electronics industry, smart home industry communication industry, automotive industry, etc.

Machine Configuration:

Machine Size:8400*2300*2700mm

Machine Efficiency:10-12pcs/min

Machine Power:2800w

Air Pressure/Voltage: 0.4-0.7Mpa/220V AC