Product Center

It is widely used in fields such as door and window hardware, aerospace, precision electronics/electrical appliances, warehousing and logistics, auto parts, and high-end intelligent services.

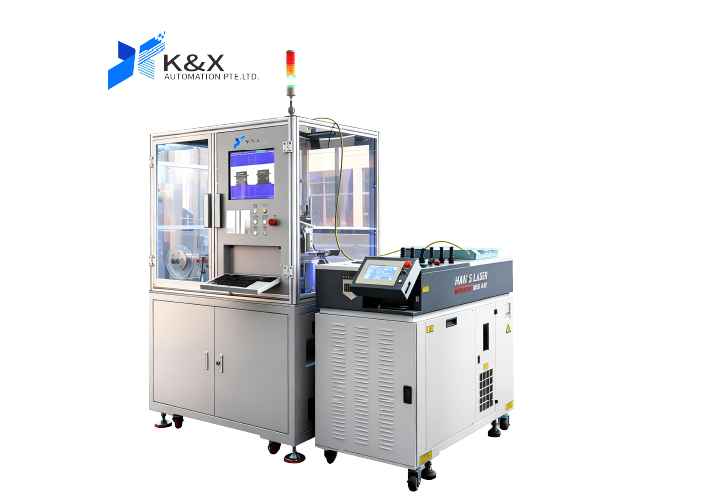

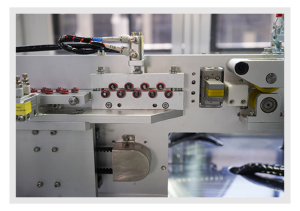

Twist Pin Cutting and Welding Machine

PRODUCT INTRODUCTION

Machine Details:

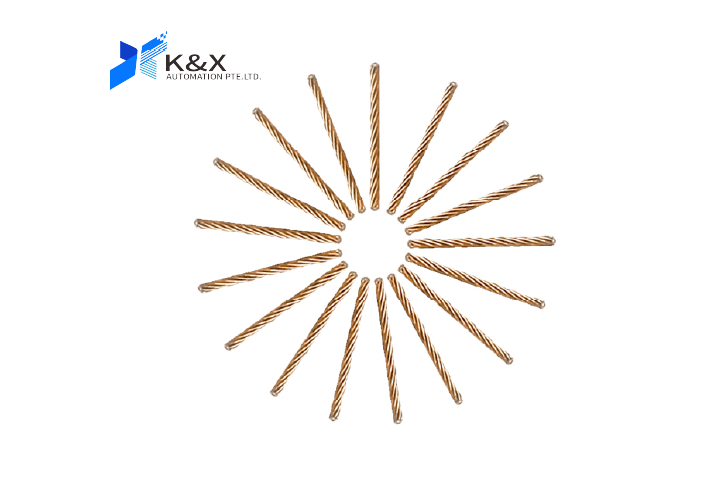

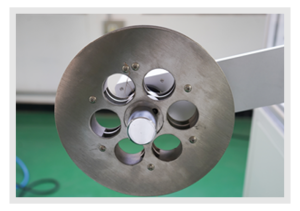

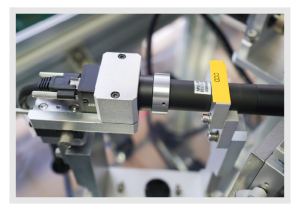

Twist Pin Automatic Cutting and Welding Machine for twist pin is mainly used for cutting and welding both ends of twist pin braided wire. The reel with twist wire is fed, cut by the wire feeding and cutting mechanism after the secondary simple straightening mechanism, the cut product is clamped and rotated by the clamping and rotating mechanism, the two ends of the product are welded by the laser welding mechanism, and the product length and welding spot are detected by the visual inspection mechanism before output. The equipment is equipped with a wire missing detection mechanism to detect whether there is a wire missing; It is equipped with visual inspection mechanism to detect the cutting length (accuracy can reach ±0.02mm) and whether the solder joint is smooth, free from deviation, loose wire, virtual welding, too large and insufficient solder joint, which ensures the high stability and quality of the equipment and greatly improves the production efficiency of the whole machine.

Function Highlights:

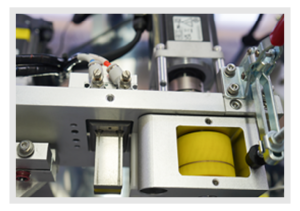

1. Constant tension wire release:

The wire release module is matched with a tension controller, so that the wire release speed and tension are stable and reliable.

2. Intelligent detection:

With CCD intelligent detection, the product length and welding quality can be detected to improve the quality of finished products.

3. High-precision wire feeding:

servo modules are used for wire feeding and laser welding to ensure stable and accurate wire feeding accuracy and reliable welding quality.

4. Modular equipment:

The equipment is with modularized design, easy to disassemble and maintain, and has high flexibility.

Application field:

They are widely used in industries such as aerospace, national defense and military, precision instruments, and medical devices.

Machine Configuration:

Machine Size:1500mm*700mm*1850mm

Machine Efficiency:10-13Pcs/Min

Machine Power:7.5KW

Air Pressure/Voltage: 0.4-0.6Mpa/220V AC